Intro: the tiny and elusive K39

The K39 is the worlds' smallest case with discrete GPU support. No one really knows where it came from; there are several K39 variants listed on Chinese shopping site Taobao. There's even one listed on Amazon, with Prime shipping to boot, but at $148 with no PSU, it's of questionable value.

|

| K39 specifications |

The K39 is an odd case; it throws away…every feature…to achieve its small size. It has no drive bays, no external ports, and of course no lighting. Instead, it relies on onboard storage and rear I/O ports (though it is worth noting there are obscure K39 variants with a single USB port and a single 3.5mm jack). However, it is incredibly small - at 3.9 to 4.5L depending on the variant, it is even smaller than the 5.0L NFC SkyReach 4 Mini. Like the S4 Mini, it is limited to short (180mm) video cards. It also supports standard flex-ATX PSUs, though there are many caveats...

The K39 power supply

While the K39 can mount generic flex-ATX PSUs, it is, for all intents and purposes, a case with a built-in PSU. The K39 PSUs are very cheap 80Plus Gold rated units, built from recycled server parts.

In order to make the PSU more compact, the stock cable harnesses are cut short and soldered into a modular breakout board. Innovatively, the PSU uses thin, high-temperature silicone wire, which is both flexible and capable of carrying high currents. Due to cable routing restrictions, the modular cables are more or less essential for operation.

While it is possible to buy a K39 with no power supply, there isn't really a reason to do so. The modular supplies cost much less than the competition, and are available up to 600W, which is much more than the case can dissipate.

The build

The actual computer inside this case is strange and sort of terrible. It uses a long-discontinued ASRock X99 board, a 120W 14-core Xeon, and an R9 Nano. The ASRock board has gained some sort of strange cult following and costs as much now as it did new (or maybe there are a ton of people who need 128GB on an ITX board?). The Xeons are very cheap, but not very fast, with any cost savings over a Ryzen 3000 CPU immediately nulled by high motherboard prices. The Nano was never very good, it performs somewhere between a 1060 6GB and a 1070, but is crippled by its 4GB of VRAM. A dubious perk is that it is almost the fastest short card supported by macOS; the

AXRX 5700 ITX can only be imported from China for a huge amount of money.

However, the components serve their purpose as being a maximum challenge testbed for the build. The X99e-ITX/ac is a very hard board to build around, especially with a 47mm cooler restriction. My previous

thin X99 build had an 83mm clearance which was still quite difficult to work with - it required a discontinued Cooler Master cooler, custom waterjet stainless brackets, and a machined-down 120mm fan. The Nano's TDP is also at the top end of short cards; the other contenders (the 1070, RX 5700, and 2070) have similar ratings.

Build notes

There's surprisingly little to say here. The K39 variants are all a little awkward to work with because they require a complete disassembly for component installation. On this flavor, the front panel comes off to reveal a freestanding motherboard tray. The I/O shield pops into the outer shell, then the tray with installed motherboard and riser slides in. The PSU and PSU cables go in next, followed by wiring, the GPU, and finally the front panel. This is where the super-flexible PSU cables come in handy; it would be impossible to route normal cables in the case.

The standard PSUs actually have a SATA power connector on them, but there is no room in the case for a 2.5" drive. My understanding is that folks who have 2.5" drives in the case use foam tape to affix them to one of the side panels.

Cooling

I was targeting a laptop-like acoustic profile on this build; that is, quiet when idle and loud and hot under load. I had originally wanted to use a 1U Dynatron vapor chamber active cooler. Unfortunately, the Dynatron was more or less unusable; it ran extremely hot (60C! at idle) and was amazingly loud. Even with a 50mV undervolt and a custom fan curve that ran minimum speed until 75C, the blower would randomly spool up with even one core active.

It was clear that some more "engineering" was needed. Fortunately, 47mm just barely clears a 1U passive cooler (29mm) with a 15mm thick fan stacked on top. To find a fan, I took to the trusty old technique of disassembling stock coolers; stock coolers are often laughed at, but to get sufficient cooling performance out of a small, cheap heatsink requires a serious fan. I ended up using a 70mm, 8.4W fan out of an FM2+ stock cooler:

The fan required a bit of minor machining (it had mounting feet that put it over the height limit). Some brackets were drawn up and printed…

…and the whole thing was put together with some screws and 3M VHB tape.

The small 40mm fan is critical; without it, the CPU would cook the SSD enough to severely throttle, meaning a lengthy cooldown period was necessary after heavy loads. It also cools the PCH by about 15C, which is not too bad for such an anemic fan.

The cooler bolts into place neatly, and the VHB seems to handle the high temperatures just fine.

Performance

We'll start with the bad news: the 2683 v3 is no longer fast. It does score a healthy 180 fps on KeyShot, but that's merely the performance of a 9900K, a CPU with six fewer cores. On the other hand, it does perform like a $350 CPU for $120, so if rendering is all you do it's not a bad choice.

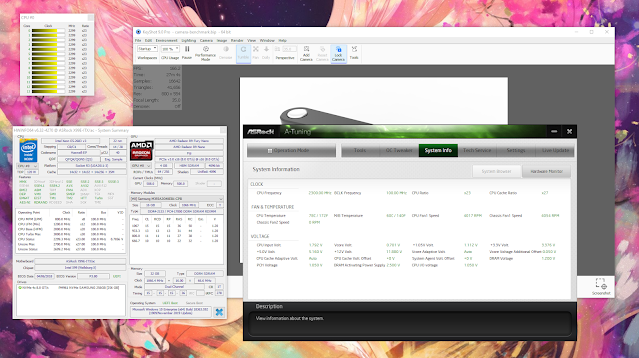

There are a couple ways to tweak performance. An X99 + Xeon specific is to undervolt the CPU by 50mV. Furthermore, most boards allow custom-tweaked fan curves:

This is pretty necessary with a small, noisy fan; most boards idle too high by default. With a tweaked fan curve and small undervolt, the CPU idles at a slightly-warm-but-not-concerning 50C:

And a fairly nominal 66W:

Load is much more interesting. Most boards have some manner of power tuning available. On this particular board, the electrical design current (EDC) was settable, but unfortunately, the limit did not seem to correspond to actual amps. Thankfully, it was monotonic...setting an EDC of 80 resulted in a load power consumption of about 180W:

Delta-over-idle of 114W corresponded to an all-core speed of 2.3GHz and a load temperature of 78C.

Importantly, neither the SSD nor the DIMMs overheated, though the memory does get quite warm:

Removing the current limit results in 200W even of power consumption, representing a 134W delta-over-idle.

At this point, the fans get really loud, but temperatures are still in control:

The RAM is now looking uncomfortably hot - some heatspreaders might be warranted...

Conclusion

We learned today that it is possible to dissipate 135W with a 47mm cooler. We also learned the importance of ambient airflow - the 40mm fan doesn't move much air, but was absolutely critical for success. In addition, we learned that Haswell Xeons have underwhelming performance in 2020, though for the price they are pretty solid. Fortunately, a lot of this is still applicable to the upcoming Ryzen 5000 CPUs; 135W is perfect for getting stock performance out of a 105W Ryzen 5000. True masochists might also consider the EPC621D4I; with careful tuning, a 28-core Xeon Platinum may be possible.